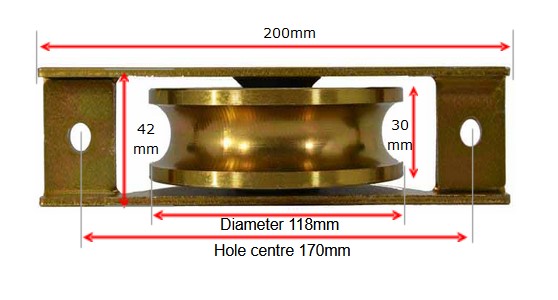

Sliding Gate Wheel/Rollers for U Groove 120mm internal Double

WH408

2.5400 kg

| Buy More & Save More | Price (GST Exclusive) |

|---|---|

| 10 units | $ 31.82 per unit |

| 20 units | $ 30.45 per unit |

| 50 units | $ 29.09 per unit |

Description:

Sliding Gate Wheel/Rollers for U Groove 120mm internal Double Bearing

Sliding gate component wheel or rollers U groove 120mm Dia internal - Double bearing

Rated to carry 350kg each wheel

Tigerlink Hardware is Sliding Gate Automation Kits and Accessories supplier. We have full range of Sliding gate hardware

Wheels & Castors. High Quality Products. Very Competitive Prices. Over 20 Years Experience. freindly Staff.

Stronger and Heavyduty wheels.

Zinc - Finished

In Most cases 2 wheels are enough for Sliding gates upto 5M, if you want to add any extra wheels 2 at each end 200-300mm aparts would be better then adding a third wheel in the middle. A middle wheel would take all the weight if there is any rises in the floor track and would shorten the life of that wheel. 2 wheels or 4 wheels is the right way to do this.

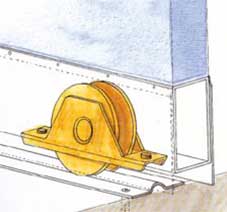

Installing a sliding gate wheel involves a few key steps to ensure the gate operates smoothly. Here’s a step-by-step guide to help you install it:

Materials Needed:

- Sliding gate wheel

- Measuring tape

- Cutting machine

- Drill and drill bits

- Screws and bolts

- Wrench or screwdriver

Steps for Installation:

Prepare the Gate and Track:

- Before installing the wheels, ensure that your sliding gate is already installed and that the sliding track is properly laid out.

- The track should be level and secure to ensure smooth operation.

Step One:

Measure the sliding gate wheel cradle, ensuring there's enough space to attach the wheel to the steel frame. Use a cutting wheel to make the cut, but first, drill four holes (one in each corner) using an 8-10mm drill bit. This will ensure the square hole is clean in each corner.

Step Two:

Clean up the rectangular hole with a file to ensure smooth edges, then spray the area with galvanized paint for protection.

Step Three:

Place the sliding gate wheel into the cut-out and check that it can rotate freely. Ensure there’s enough space for securing the wheel with a tek screw.

Step Four:

When screwing in the tek screws, make sure the wheel is aligned with the edge of the steel. The last thing you want is for the wheel to be out of alignment. Avoid welding the wheel if possible, as this can make replacement more difficult later on.

Step by Step

1. How to join Floor Track

2. Installing the Gate Wheel

3. Double and Single Bearing Wheels