Description:

Description

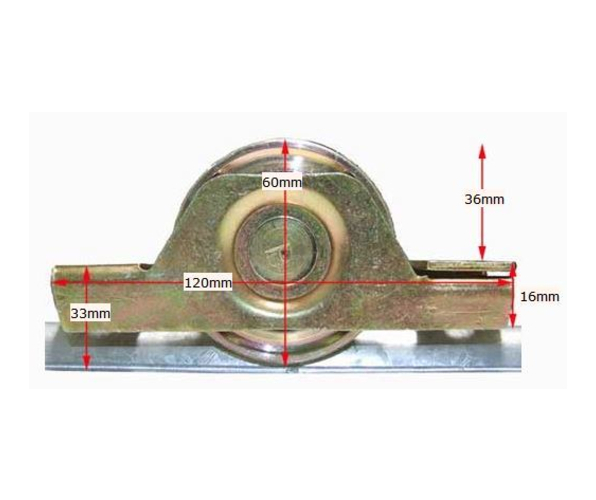

Introducing the U-Groove Sliding Gate Wheel Rollers, the ideal solution for smooth and efficient operation of your sliding gate. These rollers are specifically designed for U-groove tracks, ensuring a secure fit and reliable performance.

Featuring a 60mm internal diameter and equipped with double bearings, these gate wheel rollers provide exceptional stability and durability. The double bearings allow for effortless movement, reducing friction and ensuring a quiet and smooth sliding motion.

Crafted from high-quality materials, these gate wheel rollers are built to withstand the elements and heavy use. They are resistant to rust and corrosion, making them suitable for outdoor applications. Whether you have a residential or commercial sliding gate, these rollers are designed to handle the job with ease.

Installation is quick and straightforward. Simply place the U-groove sliding gate wheel rollers onto the track, and you're ready to enjoy effortless gate operation. The smooth movement and reliable performance of these rollers will enhance the convenience and functionality of your sliding gate system.

Upgrade your sliding gate with the U-Groove Sliding Gate Wheel Rollers and experience the benefits of smooth and reliable operation. Enjoy the convenience and peace of mind knowing that your gate will open and close effortlessly every time.

Double Bearing support Max capacity weight 200 kg per wheel

Installing a sliding gate wheel involves a few key steps to ensure the gate operates smoothly. Here’s a step-by-step guide to help you install it:

Materials Needed:

- Sliding gate wheel

- Measuring tape

- Cutting machine

- Drill and drill bits

- Screws and bolts

- Wrench or screwdriver

Steps for Installation:

Prepare the Gate and Track:

- Before installing the wheels, ensure that your sliding gate is already installed and that the sliding track is properly laid out.

- The track should be level and secure to ensure smooth operation.

Step One:

Measure the sliding gate wheel cradle, ensuring there's enough space to attach the wheel to the steel frame. Use a cutting wheel to make the cut, but first, drill four holes (one in each corner) using an 8-10mm drill bit. This will ensure the square hole is clean in each corner.

Step Two:

Clean up the rectangular hole with a file to ensure smooth edges, then spray the area with galvanized paint for protection.

Step Three:

Place the sliding gate wheel into the cut-out and check that it can rotate freely. Ensure there’s enough space for securing the wheel with a tek screw.

Step Four:

When screwing in the tek screws, make sure the wheel is aligned with the edge of the steel. The last thing you want is for the wheel to be out of alignment. Avoid welding the wheel if possible, as this can make replacement more difficult later on.